CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) have revolutionized the way jewelry is conceptualized, designed, and manufactured, making the process more efficient and precise. Let’s explore how CAD and CAM are used in jewelry design:

Computer Computer

Aided Aided

Design Manufacturing

Advantages of CAD and CAM

Higher Precision

Greater Efficiency

Consistent Results

More Client Input

Superior Product Complexity

The Computer-Aided Design Process

- Conceptualization: Designers can brainstorm ideas and visualize concepts in the virtual environment before physically creating the jewelry piece.

- Precise modeling: CAD software offers precise tools to create complex shapes, textures, and patterns, enabling the creation of intricate and unique jewelry designs.

- Iterative design: CAD facilitates easy modifications and adjustments to the design without having to start from scratch, saving time and effort.

- 3D visualization: Designers can view and present their jewelry designs in 3D, offering a more realistic representation to clients and stakeholders.

- Rendering and animation: CAD software often includes rendering capabilities, allowing designers to produce high-quality images and even animations of the jewelry piece for marketing purposes.

- Collaboration: CAD designs can be easily shared with clients, manufacturers, and other team members, making collaboration more streamlined.

- It All Starts with the Idea

A client has an idea for a piece of jewelry they would like made, and sketches and describes the idea in terms of materials, size, and shape.

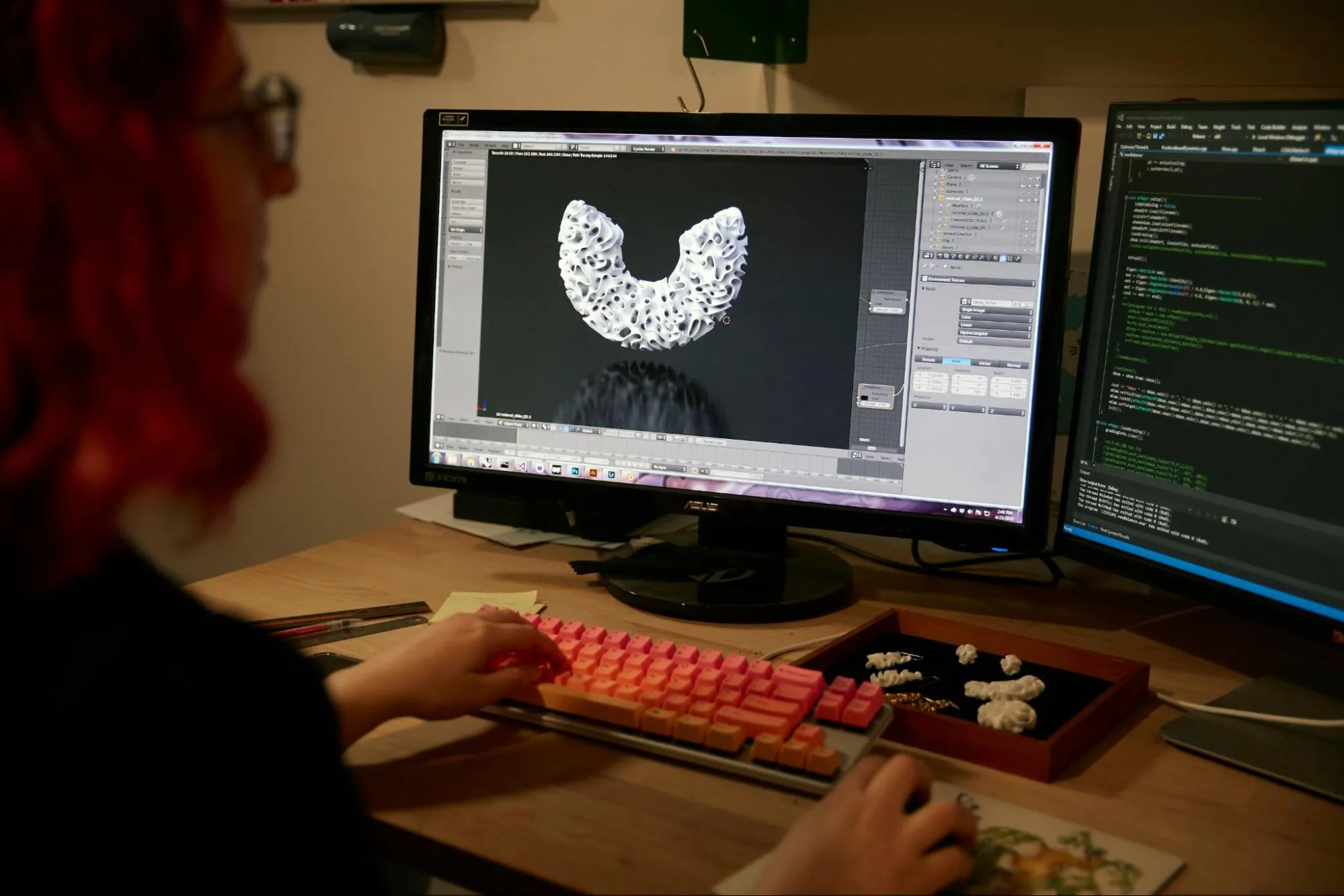

- A Visual Prototype is Created with a 3D modeling program

An artist specializing in programs like Matrix, Rhino, ArtCAD, or JewelryCAD builds a 3D model in one of those programs based on the 2D sketches. Revisions are common to get the design just right.

- A Prototype 3D Model is Created

A model of the jewelry is created from wax or metal. A rapid prototyping 3D printer can build a stunning 3D wax model. Metal models can also be created as a computer numerical control (CNC) metal mold. While more expensive, these produce the best quality results and make ideal master models for large quantities.

The Computer-Aided Manufacturing Process

- CNC Machining: Computer Numerical Control (CNC) machines are used to carve or mill the jewelry piece from a block of raw material (e.g., metal or wax) based on the CAD design.

- 3D Printing: Additive manufacturing, specifically 3D printing, is used to create wax models or directly print metal components in some advanced cases, which are then used in traditional casting processes.

- Laser Cutting: CAM can also control laser cutting machines to produce intricate designs on sheets of metal or other materials.

- Engraving and Stone Setting: CAM aids in automating processes like engraving and stone setting, ensuring precision and consistency.

- Prototyping: CAM allows for the rapid production of prototypes, enabling designers to assess the physical form and fit of the jewelry piece before proceeding to full-scale production.

- Make Molds for Your Jewelry

Once a master model is finalized, a rubber, silicone, or metal mold is produced. These are the inverse, or “the negative” of your design and are used to mass-produce your complete order.

- Jewelry is Cast from the Mold

For large orders, artisans employ the modern version of an ancient technique called lost wax casting. A powder investment is mixed to create a cream that is poured around the wax model. The wax is then melted and precious metals are injected into the space to form each piece.

Single pieces can also be created through direct metal machining, though this is more expensive.

- Laser Welding is Used for a Clean Result

Artisans use laser welding rather than soldering because it is more localized, doesn’t damage the surrounding metal and gemstones, and cleans blemishes as it goes.

- Your Jewelry is Finished to the Desired Texture

Artisans give your pieces a raw, mirrored, tumble, or matte-style finish according to your specifications. Different parts of each piece can have different finishes.

- Mount the Setting, Engrave the Pieces, and/or Apply Enamel to Your Finished Pieces

- Artisans can mount any settings for precious stones or embellishments in your design. You can choose from bezel, channel, flush, gypsy, prong, pavé, and bead settings.

- Artisans can engrave any desired patterns or words into your pieces according to your design.

- Artisans can apply a thin layer of glass enamel onto your metal to create colors. This glass is made up of iron oxide, quartz sand, borax, and potassium oxide.

- Jewelry is Polished and Completed

After all other steps are completed, artisans polish and complete your pieces and they are ready for collection or shipping.

The jewelry manufacturing industry has seen a lot of changes over the last couple of decades, with computer-aided design (CAD) and computer-aided manufacturing (CAM) opening up new possibilities for innovation.

The Computer-Aided Jewelry Design & Manufacturing Process

Once the jewelry design is finalized using CAD, CAM comes into play for the production phase. CAM software uses the digital design data to control and automate manufacturing processes. Here’s how CAM is used in jewelry design:

Using CAD software, artisans create a computer-aided jewelry design based on your ideas. Once a design is chosen, artisans use computer-aided manufacturing to produce precise and consistent jewelry molds.

Your jewelry will then be crafted using different manufacturing processes, including lost wax casting, and direct metal machining. Our skilled artisans cast, weld, and finish, your jewelry to perfection.

By integrating CAD and CAM technologies, jewelry designers can streamline their creative process, reduce production time, minimize material wastage, and produce highly detailed and intricate jewelry pieces with unparalleled accuracy. This has contributed to the growth and innovation in the jewelry industry in recent years.

Advantages of CAD and CAM in Jewelry Design and Manufacture

In the past, jewelry designers only drafted their designs by hand. For each change, they would have to start over again—making design a long and tedious process. With CAD & CAM jewelry design, the process of creating a visual prototype from which to mold and cast jewelry is much more precise and efficient.

CAD software allows designers to include detailed information about materials, processes, and dimensions that will be sent to the 3D printers and CNC (Computer Numerical Control) machines for consistent results.

Another advantage of CAD & CAM jewelry design is the ability to create jewelry designs that are much more complex and intricate than when everything is done by hand. Clients can more easily customize their jewelry and have more input in the design process, creating fashion jewelry that incorporates more of their ideas and personal style.

Consult with An Expert About Your CAD & CAM Jewelry Today

It’s easy and quick to get your jewelry manufactured with our cutting-edge technology, and as you’ve seen, we make a complicated process simple by providing CAD & CAM jewelry design, as well as the necessary tools, equipment, and skilled expertise.